How Three-Phase Induction Motors Work

How Three-Phase Induction Motors Work: A Comprehensive Deep Dive

Three-phase induction motors are the workhorses of industrial and commercial applications, powering a wide range of machinery from pumps to conveyors. This article will explain the workings of these motors, providing you with the knowledge you need to specify and maintain them.Torges Brake and Clutch

The Basics: Three-Phase Induction Motor. Operation Principles three-phase

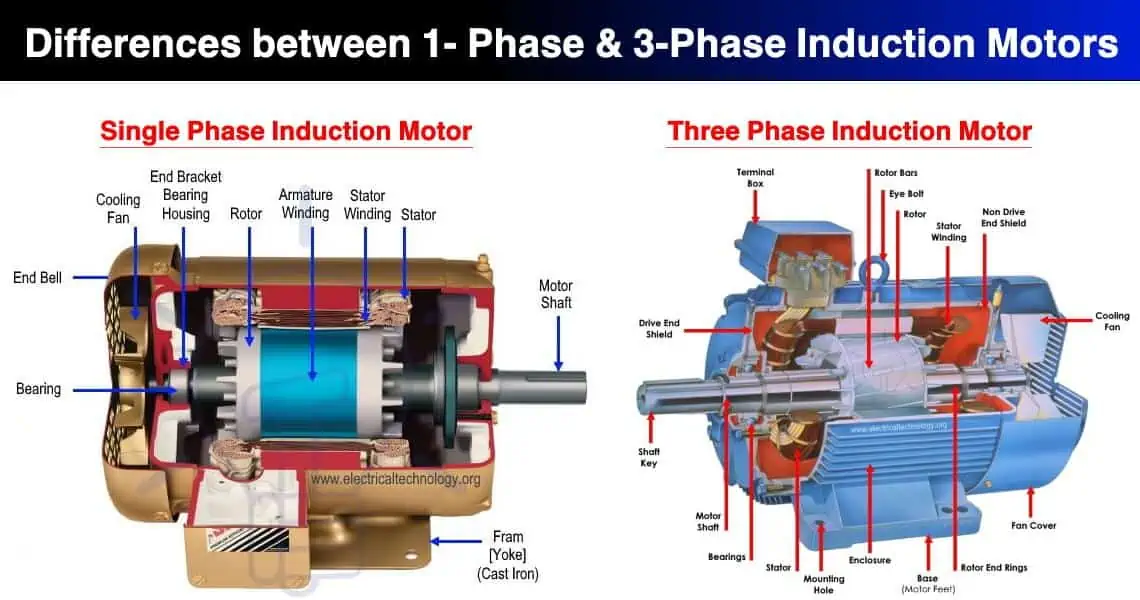

Figure 1. The operation of a three-phase motor.

Stator: The stator is the stationary part of the induction motor. It contains three sets of windings spaced 120 degrees apart. These windings are connected in star or delta to a three-phase power supply.Rotor: The rotor is the interior part of the motor that is free to rotate. The rotor can be either a squirrel-cage or wound type. Squirrel-cage rotors are the most popular due to their simplicity and ruggedness.Air Gap: The space between the stator and the rotor is called the air gap. This area plays an important role in the efficiency of the motor. In order to achieve proper operation, the air gap must be maintained within a specified tolerance. Running three-phase

Figure 2. A schematic of how a three-phase motor operates.

Power Supply: When a three-phase power supply is connected to the stator windings, a rotating magnetic field is generated. The direction of rotation depends upon the sequence of the three-phase supply.Rotating Magnetic Field: The rotating magnetic field induces voltage in the rotor windings via electromagnetic induction. This voltage causes a current to flow in the rotor, producing its own magnetic field.Rotor Movement: The interaction between the stator’s rotating magnetic field and the rotor’s induced magnetic field produces torque. This torque turns the rotor, causing the motor to rotate.

Synchronous Speed: The speed of the rotating magnetic field is referred to as synchronous speed, which is a function of the number of poles in the stator windings. The rotor never moves at this speed. Instead, it moves close to this speed and then lags slightly behind the magnetic field, creating slip.

Slip and Motor Speed

Slip: Slip is represented as the difference between the synchronous speed and the actual speed of the rotor compared to synchronous speed, in terms of percentage.

Torque and Speed Relationship: The torque that the motor produces is directly proportional to the difference between the synchronous speed and the speed of the rotor. As load on the motor increases, the slip and torque also increase.

Advantages of Three-Phase Induction Motors

Robust Design: Because they don’t have brushes or commutators, these motors are more durable and require less maintenance than other electric motors.

High Efficiency: Continuous power means high efficiency and reliability, which are characteristics of three-phase induction motors.

Widespread Applications: Because of their robustness and their reliability, they’re used in everything from industrial machinery to the gear motors that keep your washer and dryer spinning.

Conclusion

Three-phase induction motors rely on the electromagnetic induction described by Faraday’s Law to produce energy, create a magnetic field that rotates the rotor and produces work output. The motors are simple, and they’re one of the most reliable and efficient tools for turning electrical energy into mechanical work, which is why they’re used in so many industries. For people who work on electrical systems and machinery, understanding the basics of these motors and their operation is essential.

- Post published:September 7, 2023

- Post category:Motors